One of the most noticeable changes in product labeling today is the use of shrink sleeves. They wrap around the product's container and offer many creative ways to take advantage of their flexibility.

Many consumers like the attractive and modern aesthetic of shrink sleeves. However, there is more to them than just looks. Here are some of the benefits you’ll get when you switch to shrink sleeves and how they can improve your sales.

1. Sustainability

Shrink sleeve labels today use green materials, which make it easy for recycling or biodegradation. They’re easy to add and easy to remove, making them a better option than plastic or PVC. You can use this to your advantage and promote your green efforts to your audience.

RELATED ARTICLE: What Are Shrink Sleeves and Why Should You Consider Them for Packaging?

The popularity of sustainable products continues to improve each year. 2021 is said to sell $10-18 billion worth of products more than 2019. Consumers are steadily choosing to shop “green” over other options. With sustainable packaging, your sales can skyrocket!

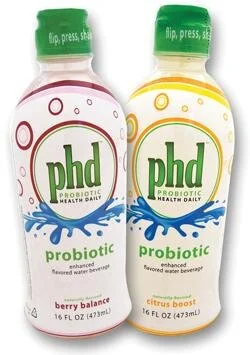

2. Take Your Product’s Creativity to the Next Level

Shrink sleeves allow you to get creative. You can create a shrink sleeve to fit your product exactly the way you want. By satisfying the consumer’s need for unique packaging with your production, you can improve sales. Studies show that eye-catching packaging retains customers, with many deciding to buy again. They will also associate your brand image with how your product presents itself.

3. Prevents Tampering

A broken shrink sleeve is a sign of tampering. Therefore, these labels prevent any backlash towards your company in case of tamper-related issues. Product liability can cost a company tens of thousands of dollars in settlements and legal costs. Tamper-proof packaging can help to build customer trust, resulting in improved sales over time.

RELATED ARTICLE: How to Read CBD Labels Like a Pro

4. Faster Production

Shrink sleeves use the latest technology, with a digital press making it easy to create labels. You can meet the demand for seasons like Christmas or other holidays. It also makes it easy for you to keep up if you ever experience a spike in sales — which you likely will when customers are able to spot your speedy and reliable production and delivery.

5. Improves Brand Awareness

Having eye-catching and unique packaging helps keep you in consumers' minds. As you improve your brand and products across the board, you will increase your revenue. Businesses improve their sales by over 20% if they can consistently deliver their brand image. Shrink sleeves can help you effectively communicate who you are without you having to spend much to do it.

6. Cost-Effective

Finally, the use of shrink sleeves is incredibly cost-effective. Having a single wrap-around label is far cheaper than creating separate front and back labels. You can also opt to have only a part of the item within the sleeve.

RELATED ARTICLE: 3 Reasons That Custom Product Labels Matter

Some companies even use the sleeve to wrap bundles together, saving on the cost of packaging. If you were to use shrink sleeves to reduce packaging costs for your 2-pack bundles, you are essentially saving half of your budget.

Try Shrink Sleeves for Yourself

Proper packaging communicates all the right things. It helps establish your message and identity to consumers. Shrink sleeves offer so much more than traditional packaging — just see for yourself.

Century Label offers shrink sleeves that can help elevate your business. Our labels provide both flexible functionality and unique aesthetic appeal for any product. Get in touch to learn more about our shrink sleeve capabilities.